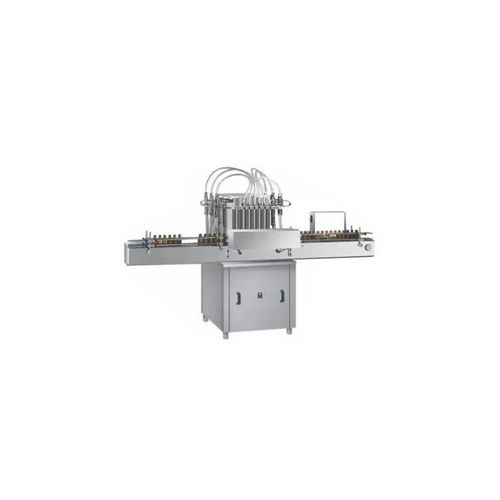

Tube Filling Machine

Tube Filling Machine Specification

- Product Type

- Filling Machine

- Material

- Stainless Steel

- Application

- Beverage, Food, Medical

- Packaging Material

- Paper, Plastic, Wood

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

- Weight (kg)

- 700 Kilograms (kg)

- Dimension (L*W*H)

- 1800 Millimeter (mm)

- Capacity

- 50 Pcs/min

- Feature

- High Performance, Low Noise, Lower Energy Consumption, High Efficiency, Stable Performance, Simple Control

- Color

- Silver

- Warranty

- 1 Year

Tube Filling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- INDIA

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 1 Months

- Sample Available

- No

- Packaging Details

- Standard Packing As Per Client's Requirement

- Main Export Market(s)

- Africa, Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East

- Main Domestic Market

- All India

- Certifications

- IEC

About Tube Filling Machine

Key Features of Tube Filling Machines

1. Tube handling: The machine can handle tubes of various sizes, materials, and shapes.

2. Filling system: The filling system can be piston-based, pump-based, or auger-based, depending on the product's viscosity and filling requirements.

3. Dosing accuracy: The machine can accurately measure and fill the desired amount of product into each tube.

4. Sealing system: The machine can seal the filled tubes using various methods, such as heat sealing, ultrasonic sealing, or crimping.

5. Speed and productivity: Tube filling machines can operate at high speeds, filling and sealing hundreds of tubes per hour.

6. Easy cleaning and maintenance: The machine's design allows for easy cleaning and maintenance, reducing downtime and ensuring efficient operation.

Types of Tube Filling Machines

1. Semi-automatic tube filling machines: Require manual loading and unloading of tubes, but automate the filling and sealing process.

2. Automatic tube filling machines: Fully automate the tube filling and sealing process, including loading and unloading of tubes.

3. Rotary tube filling machines: Use a rotary system to fill and seal tubes, allowing for high-speed operation.

4. Linear tube filling machines: Use a linear system to fill and seal tubes, providing more flexibility in terms of tube size and shape.

Benefits of Using Tube Filling Machines

1. Increased efficiency: Automate the tube filling and sealing process, reducing labor costs and increasing productivity.

2. Improved accuracy: Ensure accurate filling and sealing of tubes, reducing waste and improving product quality.

3. Enhanced product safety: Use sterile or sanitized tubes and filling equipment to minimize the risk of contamination.

4. Reduced labor costs: Minimize manual labor required for tube filling and sealing, reducing labor costs and improving workplace safety.

5. Customization options: Choose from various machine configurations and options to meet specific product and packaging requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Filling Machine Category

Bottle Filling Machine

Price 330000.0 INR / Unit

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Material : Stainless Steel

Drive Type : Pneumatic

Computerized : No

Viscous Liquid Filling Machine

Price 1050000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Material : Stainless Steel

Drive Type : Pneumatic

Computerized : Yes

Milk Filling Machine

Price 315000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Material : Stainless Steel

Drive Type : Electric

Computerized : Yes

Liquid Filling Machine sarvo base

Price 850000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Stainless Steel

Drive Type : Electric

Computerized : Yes